I know I've been absent but the sad truth is that the temporary garage spot I got while not working on my car (barely big enough to fit my car in) has become my permanent spot.

Talking to the rest of the guys and trying to get them to understand that I can't remove the interior if I can't open my doors didn't do much good so for now I'm content with the fact that the car is indoors and warm.

In the meantime I'm looking for a new garage so most likely no new posts for another month or so. Sorry.

Monday, December 24, 2007

Sunday, October 21, 2007

Picking up the slack

Still, I managed to get the engine in and done as seen in the picture to the right. I would have loved to do the AC unit properly as well but at the time I was still hoping that the company that sold me the car would pick up the bill for the restoration of it so I didnt touch it. As it stands now, I'm guessing I'll pay for it though.

On a somewhat brighter note I picked up my new TA Performance headers a couple of weeks ago that I ordered sometime in March if I recall correctly. Overseas shipping is a nightmare.

I've also decided to replace my Flowmatser 40 mufflers with the Dynomax Super Turbo's after checking with the V8Buick forum members. The 20" muffler was the recommendation but I can squeeze in the 16" at best so I'm still waiting on feedback on if that's an option.

I'll be tackling the interior this winter - or as much as I can afford at least as I'm running low on funds for various reasons. Shipping parts from the States is also an issue so I'll try and do as much as possible on my own.

Post frequency will still be a bit erratic in the next month or so until I get back to the garage mid November.

More pictures:

Saturday, May 5, 2007

Replacing the sheet metal below the battery tray

As I've mentioned before the sheet metal beneath the battery tray was in pretty bad condition.

As I've mentioned before the sheet metal beneath the battery tray was in pretty bad condition. This section is made up of sheet metal from the inner fender as well as the front assembly, lying on top of eachother which makes it rather cumbersome to repair.

With the time and money constraints I have we therefore went another route and cut out the rotten metal with the fender and the front assembly still in the car.

This meant that we couldn't do a perfect job but for the time being it is quite adequate. My intentions are to replace or repair this properly when I do a frame-off restoration of the car in 5-7 years time.

Engine assembly

The assembly of the engine is coming along nicely. I got one of the valve covers painted and although I wasn't sure about it at first, I like it more and more now.

The assembly of the engine is coming along nicely. I got one of the valve covers painted and although I wasn't sure about it at first, I like it more and more now.There's also been a lot of stuff painted and "chromed" the past days (just click on through the images from the one I linked).

I will still need to touch up some of the paintwork as it got scratched during re-assembly, no matter how careful I (thought) I was.

Monday, April 30, 2007

The rest

Just a small "misc" post to inform you about all the little things that I did the past weekend.

I bent some new trans cooler lines. I also had to bend a new brake line as the one I bought was too short.

I didn't get a chance to replace the rotten sheet metal as Reijo was out of town (I'm not a good welder and he's a great welder so better wait for him ;).

Hopefully I'll be able to swing by the garage later today (despite my cold) and tomorrow (holiday here in Sweden).

I bent some new trans cooler lines. I also had to bend a new brake line as the one I bought was too short.

I didn't get a chance to replace the rotten sheet metal as Reijo was out of town (I'm not a good welder and he's a great welder so better wait for him ;).

Hopefully I'll be able to swing by the garage later today (despite my cold) and tomorrow (holiday here in Sweden).

Even more painted

These posts all start to look alike but that's because there's a lot to be painted right now. Despite it taking time it's still fun to see everything coming together.

These posts all start to look alike but that's because there's a lot to be painted right now. Despite it taking time it's still fun to see everything coming together.

Friday, April 27, 2007

The latest stuff

Not a lot done done since the last post but that's mostly because cleaning and painting the engine parts takes time. Not to mention that removing the old lines took for ever.

Not a lot done done since the last post but that's mostly because cleaning and painting the engine parts takes time. Not to mention that removing the old lines took for ever.I did get quite a few engine parts painted. I also got new brake lines to replace my old ones.

I'm hoping to replace all the sheet metal for the battery tray by tomorrow as well as shape and install the new brake lines.

A deadline!

One of my garage buddies got me a time at the DMV the 22'd of May so now I have to get busy. :)

This is good because I have an actual date that I have to have the car done. It's bad because now I have to work on the car even if/when I don't feel like it which might affect the quality of the work done.

Still, no turning back now. :)

This is good because I have an actual date that I have to have the car done. It's bad because now I have to work on the car even if/when I don't feel like it which might affect the quality of the work done.

Still, no turning back now. :)

Sunday, April 22, 2007

Replacing the battery tray

The battery tray and surrounding sheet metal was long gone on this car so Reijo helped me cut out the rotten metal.

The battery tray and surrounding sheet metal was long gone on this car so Reijo helped me cut out the rotten metal.The inner fender connects to the frame via a plate that in turn is connected to the frame via a rubber bushing. This plate was in pretty bad shape as well.

We decided to keep it though and after some intense wire brushing it looked almost decent. Since it's been eaten by rust we'll reinforce it with some new metal.

After this has been done we'll fabricate new sheet metal and start repairing the fenders. Then it's just a couple of coats of paint and installing the battery tray. :)

Painting the engine

Long time since the last post - I've been busy though. :)

Long time since the last post - I've been busy though. :)I've gotten most of the engine painted, although it needs another couple of coats to look the way I want it. I've run out of paint though so I'm waiting for that at the moment.

The hardest part when painting the engine has - of course - been getting it clean enough to paint. There are a lot of nooks and crannies in an engine and it's surrounding parts.

With the use of power tool wire brushes and generous use of brake cleaning fluid (as suggested by a member of the V8Buick.com forum) I got most of the parts clean enough to paint though.

The second hardest part of this is getting paint in all of these nooks and crannies, without getting too much paint on all the other parts of the engine. I still have a couple of places where I'll need to touch up with some more paint.

I had initially planned on painting all of the bolts for the engine in black but that proved to be too time consuming (putting the engine together, paint it, taking it apart, paint the bolts, put it back together once more) so I just painted the bolts for the intake as for now.

I had initially planned on painting all of the bolts for the engine in black but that proved to be too time consuming (putting the engine together, paint it, taking it apart, paint the bolts, put it back together once more) so I just painted the bolts for the intake as for now.I might paint other bolts - for accessories and such - in red (as these parts are in black), all depending on how much time I have.

The single biggest problem I encountered was when the gasket for the oil pan crept out as I put on the oil pan. I didn't notice either so it sat like this for a day or two. I managed to reseat it pretty good though so it should stay tight.

Sunday, April 8, 2007

Painting the firewall and cutting out rust

Yesterday I painted the firewall. There are some areas that are harder to reach than others but I think it'll be quite good when I'm done.

Yesterday I painted the firewall. There are some areas that are harder to reach than others but I think it'll be quite good when I'm done.I also started cutting out rusted sheet metal from under the battery tray. I'm guessing it'll be a bit tricky to repair as the inner and outer fender overlap but I'll cut out the bad and keep as much good as possible and go from there.

Saturday, April 7, 2007

More paint!

Well, not a lot to add besides the fact that I painted even more of the engine room as well as my old headers and a couple of engine accessories.

Well, not a lot to add besides the fact that I painted even more of the engine room as well as my old headers and a couple of engine accessories.I'll try and get the firewall done today.

Friday, April 6, 2007

Time for paint

I finally got the engine room as clean as I can, given the time and money I have available, and started painting it yesterday.

I finally got the engine room as clean as I can, given the time and money I have available, and started painting it yesterday.I'm using a matte enamel acrylic paint that others in my garage has used with great success. You might wonder why I went with matte and not semi-gloss or even gloss and the sole reason is that there was no semi-gloss and I think that gloss is too shiny.

My reasoning is that with a matte engine room the engine will stand out even more (which, by the way, will be painted in proper Buick red and have semi-gloss black accessories). This might prove to be completely wrong but then I have a reason to do it again. :)

Unfortunately the paint for my engine didn't arrive yesterday and since it's Easter it won't arrive until next Tuesday at the earliest. I still have a couple of things to paint over at my brothers place (where they can dry in peace) and the engine room isn't finished either so it's not like I don't have anything to do.

Still, it'd be nice to get the engine back together. I have a pretty ambitious idea for how to paint the engine, we'll see how far I get when it comes to implementing it. ;)

Monday, April 2, 2007

Cleaning

I've spent most of the past days cleaing the engine and the engine compartment. I finished up the timing cover, the waterpump and the intake yesterday.

I've spent most of the past days cleaing the engine and the engine compartment. I finished up the timing cover, the waterpump and the intake yesterday.I also got started on the engine compartment but I'll need to go over it once more to get all the old dirt and grime out of there.

The engine will be painted as soon as I get gaskets and paint. Should be fun. :)

Sunday, April 1, 2007

Brand new parts and a gift!

Earlier this week I got the parts from TA Performance for the oil pump - all I'm waiting for now in order to put the engine back together is a set of gaskets and the paint.

Earlier this week I got the parts from TA Performance for the oil pump - all I'm waiting for now in order to put the engine back together is a set of gaskets and the paint.I quit my job this friday and as a goodbye gift I got this very nice tool box. It's not the most expensive or robust thing in the world but it's still a great place to store my tools.

Wednesday, March 28, 2007

A new wiring harness - nothing but a dream?

As my old wiring harness looks like crap I decided to buy a new one.

As my old wiring harness looks like crap I decided to buy a new one.The only problem is that the guys I'm buying it from don't have any in stock, the earliest they can have one done is in 4-5 weeks.

On top of that they might not even ship to Sweden and if they do it's via UPS or FedEx which will cost me roughly a ton of money.

Time to hit the forums and ask for advice yet again. :)

Update: I spoke to American Autowire instead and they only needed one week to build it and then another week to ship it. The best part of all is that they ship with the US Postal Services which means that shipping and insurance only added up to about $30!

So - a new engine harness within 2 weeks for around $180 (1280 Kr). Better than expected. :)

Sunday, March 25, 2007

The engine is out and is being cleaned

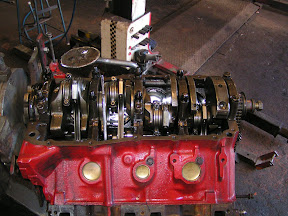

I got the engine on a stand yesterday and spent most of the day taking it apart so much that I can paint it - cleaning it in the process.

I got the engine on a stand yesterday and spent most of the day taking it apart so much that I can paint it - cleaning it in the process.All in all the innards of the engine looks really nice and clean and there's no metal filings or shavings to be found in the oil pickup filter.

The only thing that looks really bad is the gears for the MSD distributor billet, not a pretty sight at all. Here's how the cam end looks.

A handy tip: if you need to turn the crank shaft by hand, the shaft from the oil pump gear fits like a glove. :)

The cam itself looks quite alright to me - too bad about the worn out gear to the distributor.

I'll be going back to the garage this tuesday and keep on cleaning the engine and the engine bay.

Oh yeah - the old headers weren't broken, just very rusty and beat up, so I won't have to repair them. Another thing to strike from my list. :)

Wednesday, March 21, 2007

An update to my 'To-Do' list

I've updated the "Things to do this winter" list, striking out the things I'm going to wait with (or don't need to do at all) and adding a couple of other tasks that has cropped up during the journey.

It's hard to estimate the progress - especially for things like refurbishing the engine room - but I've tried to come up with a fair number.

It's hard to estimate the progress - especially for things like refurbishing the engine room - but I've tried to come up with a fair number.

Removing the engine, part 2

This past weekend I got around to getting the engine out. It wasn't all that hard, it just took some more or less tedious work. :)

This past weekend I got around to getting the engine out. It wasn't all that hard, it just took some more or less tedious work. :)The hardest part was removing some of the bolts that connected the transmission to the engine as they weren't exactly easy to reach. I broke off a spark plug and the connection from the water temperature giver but other than that all of the bolts and nuts came off easily enough.

There's a couple of parts - like the lines to the transmission from the radiator - that I need to replace. The engine mounts seems to be in need of replacement as well.

It would also seem as if my AC compressor is mounted a bit backwards, especially compared to this picture.

Only a few parts are in bigger need of a restoration than others but it'll still take quite a bit of time and money to get the engine and the engine compartment in the shape I want it.

Still, that's the fun part. :)

Tuesday, March 20, 2007

My credit card hurts

I just got off the phone with TA Performance, ordering some parts. The ones I needed are some oil mods (almost all of them) but I really wanted new headers as well (the super competition doesn't fit my car so the "regular" competition would have to do).

When I spoke to them yesterday they explained that shipping via UPS would cost me $677 (4840 Kr)! As always, the guys at V8Buick.com came to the rescue and hooked me up with a guy from Sweden that imports cars and parts on a regular basis. He agreed to help me out with a shipping cost of about $105 (cirka 750 Kr). A lot more sane than $677.

All in all this purchase will set me back $556 (3975 Kr) + shipping, customs and VAT - a grand total of $940 (6710 Kr).

The only comfort is that right now my Visa is only charged the $556, the additional $384 is coming later (a week in the case of the oil mods, 3 months in the case of the headers). I still need a new wiring harness for the engine though...

I got a lot done during the weekend - I just haven't had time to update. I will try to rectify that asap.

When I spoke to them yesterday they explained that shipping via UPS would cost me $677 (4840 Kr)! As always, the guys at V8Buick.com came to the rescue and hooked me up with a guy from Sweden that imports cars and parts on a regular basis. He agreed to help me out with a shipping cost of about $105 (cirka 750 Kr). A lot more sane than $677.

All in all this purchase will set me back $556 (3975 Kr) + shipping, customs and VAT - a grand total of $940 (6710 Kr).

The only comfort is that right now my Visa is only charged the $556, the additional $384 is coming later (a week in the case of the oil mods, 3 months in the case of the headers). I still need a new wiring harness for the engine though...

I got a lot done during the weekend - I just haven't had time to update. I will try to rectify that asap.

Tuesday, March 13, 2007

Removing the engine, part 1

Sunday I decided to start preparing for getting the engine out as I want to get started on the oil mods as soon as possible in case I run into problems.

Sunday I decided to start preparing for getting the engine out as I want to get started on the oil mods as soon as possible in case I run into problems.The Buick factory manual has a checklist for this and the ever informative V8Buick.com had a number of pointers so it shouldn't be impossible to get this done properly. The guys I share garage space with has also done this numerous times before.

I really don't have a lot to write about here as it was very straight forward and if you need tips and tricks on this I warmly recommend the V8Buick.com thread.

My Picasa Web images for "engine removal".

Putting the dash back together

This Saturday I had planned to prepare for the engine removal but I realised that it would be better to get the dash back together first. Unfortunately working on the car felt like a chore the entire day.

This Saturday I had planned to prepare for the engine removal but I realised that it would be better to get the dash back together first. Unfortunately working on the car felt like a chore the entire day.I guess part of the reason for that feeling was that I still had some of my cold still in me. The fact that I was overconfident when I took the dash apart and had a really hard time recollecting where all the parts would go didn't make things better either.

I got the instrument cluster together except for some of the light bulbs in the instruments. The previous owners probably didn't care too much about them as I know I haven't misplaced any of them.

Another thing I couldn't reconnect due to my lackluster marking of wires is the switch to the rear window defroster. The helpful members on the V8Buick.com forum gave me some pointers that I'll try out this coming weekend.

At the end of the day I barely got the instrument cluster back in but decided to leave it at that as I needed to get working on the engine - I can work on the dash while waiting for the engine/engine room paint to dry.

The biggest headache after getting it back in was the fact that the generator light wouldn't go out even after I started the engine which means that either the generator is busted (and it worked before I stopped driving last year) or that the instrument cluster is borked.

I'll post that question to the board as well.

Thursday, March 8, 2007

A timetable and a budget

After some thinking and counting I think I've come up with a plan. I won't touch the interior anymore, just put together what I've taken apart and if things needs to be repaired (like the dash, steering column, instrument cluster, etc, etc) I won't do it - I just don't have the time.

The engine is main focus right now and I will start preparing for getting it out of the car this coming Saturday. After the engine is done I'll fix the wobbly steering and then the leaky front windshield.

I "missed" two Saturdays due to extremely bad weather and then an equally bad cold so I'll spend both this coming Saturday and Sunday in the garage. On Sunday I'll get the dash and instrument cluster back into the car.

Pretty soon I'm going to have to get me another car due to me getting a new job. This means that I'll be able to go to the garage a lot more often than before. Which is nice.

Now - since I'm ordering parts from TA Performance I'll need to wait for those to arrive and since I just now fired off an e-mail to them asking how long it'll take for those parts to arrive I really can't plan too far ahead.

Nevertheless - the dash is going in this weekend and the engine is coming out the next one after that. I'll need some time to repaint and refurbish both it and the engine room so it really doesn't matter if I'll have to wait for the parts 3-4 weeks. I'm hoping to get the engine back in mid-April by the latest.

The "must have" items from TA are the oiling system mods; TA1502 (adjustable oil pressure regulator) and TA1510 (oil pump booster plate) so I can get the oil pressure up to proper levels.

If shipping doesn't kill me I'll also order a pair of TA2012CH (competition series headers) but that's not as crucial as the oil mods.

The oil mods are roughly $45, the headers $445 and I have no idea how much shipping is. The engine and engine room paint is another $100 I would guess.

Fixing the wobbly steering column won't cost me all too much I'm hoping but I just realised that the instructions I was about to follow is for a tilt steering column only - which I don't have. Oh well, I'll take look at it while the engine's out - should be enough wiggle room then I suppose.

Replacing the window is roughly $110 - or at least that's what I've been told. I might just do this before I get the engine out, all depending on how long shipping from TA takes as I need to drive the car to the shop that does this.

So, that's the plan - at least the bigger picture. I might be able to fiddle with the interior, trunk, paint, etc as well but I'm not counting on it. I'd rather get the engine well done than rushing it in order to get everything done before the summer.

I have to have something to do this winter as well...

The engine is main focus right now and I will start preparing for getting it out of the car this coming Saturday. After the engine is done I'll fix the wobbly steering and then the leaky front windshield.

I "missed" two Saturdays due to extremely bad weather and then an equally bad cold so I'll spend both this coming Saturday and Sunday in the garage. On Sunday I'll get the dash and instrument cluster back into the car.

Pretty soon I'm going to have to get me another car due to me getting a new job. This means that I'll be able to go to the garage a lot more often than before. Which is nice.

Now - since I'm ordering parts from TA Performance I'll need to wait for those to arrive and since I just now fired off an e-mail to them asking how long it'll take for those parts to arrive I really can't plan too far ahead.

Nevertheless - the dash is going in this weekend and the engine is coming out the next one after that. I'll need some time to repaint and refurbish both it and the engine room so it really doesn't matter if I'll have to wait for the parts 3-4 weeks. I'm hoping to get the engine back in mid-April by the latest.

The "must have" items from TA are the oiling system mods; TA1502 (adjustable oil pressure regulator) and TA1510 (oil pump booster plate) so I can get the oil pressure up to proper levels.

If shipping doesn't kill me I'll also order a pair of TA2012CH (competition series headers) but that's not as crucial as the oil mods.

The oil mods are roughly $45, the headers $445 and I have no idea how much shipping is. The engine and engine room paint is another $100 I would guess.

Fixing the wobbly steering column won't cost me all too much I'm hoping but I just realised that the instructions I was about to follow is for a tilt steering column only - which I don't have. Oh well, I'll take look at it while the engine's out - should be enough wiggle room then I suppose.

Replacing the window is roughly $110 - or at least that's what I've been told. I might just do this before I get the engine out, all depending on how long shipping from TA takes as I need to drive the car to the shop that does this.

So, that's the plan - at least the bigger picture. I might be able to fiddle with the interior, trunk, paint, etc as well but I'm not counting on it. I'd rather get the engine well done than rushing it in order to get everything done before the summer.

I have to have something to do this winter as well...

Saturday, March 3, 2007

Home sick

Yesterday I caught a really bad cold and can hardly think so I'm going to have to stay home today. Previous Saturday I was home due to the very crappy weather so I'm running out of time.

I'll try and sit down today and see if I can't estimate how much time I really need to "finish" the car before early May. I can always skip certain items on my to-do list but I need to get the engine out so I can fix the low oil pressure.

Shouldn't be impossible though, as long as I get to the garage that is.

I'll try and sit down today and see if I can't estimate how much time I really need to "finish" the car before early May. I can always skip certain items on my to-do list but I need to get the engine out so I can fix the low oil pressure.

Shouldn't be impossible though, as long as I get to the garage that is.

Wednesday, February 21, 2007

New headers will have to wait

I just spoke with the company that helps me find parts for my car about headers as the one on the passenger side of the car is busted.

Initially I was told that they'd cost about 2000 Skr ($280) but I wanted to go for the TA Performance headers so I asked them for a price quote on those (they cost $445 in the States at the time of writing).

They couldn't get headers from TA but quoted me for a pair of Hooker headers instead. Unfortunately these would cost me 7595 Skr ($1060). A lot of money indeed.

So now I'll have to wait with headers until the next winter and then I'll most likely get the TA Performance headers directly from them as those are the ones I want (plus, they'll most likely be cheaper - even after shipping, VAT and customs).

For this summer I'll just weld the existing ones into usable shape.

Initially I was told that they'd cost about 2000 Skr ($280) but I wanted to go for the TA Performance headers so I asked them for a price quote on those (they cost $445 in the States at the time of writing).

They couldn't get headers from TA but quoted me for a pair of Hooker headers instead. Unfortunately these would cost me 7595 Skr ($1060). A lot of money indeed.

So now I'll have to wait with headers until the next winter and then I'll most likely get the TA Performance headers directly from them as those are the ones I want (plus, they'll most likely be cheaper - even after shipping, VAT and customs).

For this summer I'll just weld the existing ones into usable shape.

Sunday, February 18, 2007

Almost all the dash electronics done

The parts I ordered for my car came in this week; a new wiper/washer motor/pump (I was told it'd be new but it was in fact remanufactured), a relay for the fan motor and light bulbs for the dash lights.

The parts I ordered for my car came in this week; a new wiper/washer motor/pump (I was told it'd be new but it was in fact remanufactured), a relay for the fan motor and light bulbs for the dash lights.First up was the fan relay as this was the easiest one. It's not ideally located but I've got long arms so I got it back in there. Only problem was that when I went to test it all out the fan only worked at the Low setting. Sigh.

I took out the voltmeter and checked all the connections and they all had proper voltage. I followed the wiring, testing bit by bit, until I got to the fan resistor. After jostling that about the fan worked as it should so I'll take a closer look at it later on.

Next up was the wiper motor. As I mentioned above I was expecting a new unit but got a remanufactured one. There's still warranty on it and it's not extremely difficult to replace but it'd be nice to have a new one in there.

The mechanical installation wasn't all too difficult. I had to widen the gap in the plate that connects directly to the motor shaft as it was 0.1 mm to narrow. The real worries began when I hooked up the electronics.

At first it all seemed fine; the wipers and the washer pump all operated as they should but when I tried to turn the wipers off - they just kept going up and down in very small movements just at the lower turning point.

I was stumped and had no idea what it could be. I started measuring voltages just about everywhere but it all looked just fine. I finally realised that I should probably check the Fisher Body manual and after about 10 minutes of reading I located this exact problem and how to troubleshoot it.

I was stumped and had no idea what it could be. I started measuring voltages just about everywhere but it all looked just fine. I finally realised that I should probably check the Fisher Body manual and after about 10 minutes of reading I located this exact problem and how to troubleshoot it.It turned out to be the ground to the dash controls for the wiper/washer. When testing I just hooked the control switch on to the connector so there was no ground what so ever. After temporarily screwing it to the dash sheet metal the wipers worked as they should.

Rejoice!

Reijo was going to help me listen for unwanted engine sounds but he was away on an errand so I started removing old tape residue from the vinyl roof while I waited for him. As to why there's tape residue to begin with I have only myself to blame.

When the car started to take in water during the autumn rains that plagued Sweden for the better part of three months I taped over every trimming on the roof, hoping that It'd keep tight(er). It didn't help at all.

All that it did was cling to the chrome and vinyl making it almost impossible to remove. First I tried with paint thinner but it seemed a bit too aggressive against the vinyl so I bought another solvent, designed to remove old glue. I got most of it off but I'll need to go over it again later on.

All that it did was cling to the chrome and vinyl making it almost impossible to remove. First I tried with paint thinner but it seemed a bit too aggressive against the vinyl so I bought another solvent, designed to remove old glue. I got most of it off but I'll need to go over it again later on.After Reijo got back he brought out the stethoscope and listened to the engine for 5-10 minutes while I took it from idle to about 1500 RPMs. The good news is that he couldn't hear any actual noise coming from within the engine besides some very minor rattling from the valves but not enough to worry about.

There still was a sharp, clonking noise coming in relatively regular intervals. I've always attributed that to a header hitting the frame as it goes away as soon as you rev the engine past idle but Reijo wanted to listen to the oil pan with the stethoscope as well before dismissing internal problems. To do that we need to lift the car off the ground which we didn't have time for yesterday.

Still, here's hoping that all I have to do is upgrade the oil system and not replace the main and rod bearings.

Sunday, February 11, 2007

The clock to tachometer conversion

Yesterday I was determined to get the clock to tachometer conversion done. I had planned it all out in my head and knew exactly how I wanted to do it.

Yesterday I was determined to get the clock to tachometer conversion done. I had planned it all out in my head and knew exactly how I wanted to do it.I had bought a clear plastic sheet about 2 millimeters (mm) thick as well as some black, semi-gloss paint, the rest of the tools needed for the fabrication should be available in the garage.

I had already disassembled the clock and tach a week ago so I started out by measuring where the new holes was going to end up. After I created a template it was quite easy to mark and drill the holes.

Now I needed to figure out how much the old spacers in the tach had to be cut down in order to fit behind the plastic cover. 10 mm had to come off but it turns out that the inner threads for the fastening screw didn't run all the way down so I had to find a new solution.

Reijo suggested using old fuel line copper tube cut down to 8 mm (the original rise of the existing spacers were 18 mm). This worked out great and after clamping the copper tube to the screws the spacers even stayed put when installing the unit into the old housing.

Next up was to fabricate a new black cover since the tach was smaller than the clock. Again Reijo chimed in and came up with the idea to reuse the cover ring from the Autometer housing in order to create a very nice looking cover.

Next up was to fabricate a new black cover since the tach was smaller than the clock. Again Reijo chimed in and came up with the idea to reuse the cover ring from the Autometer housing in order to create a very nice looking cover.The only complication with this idea was that the rev limiter lamp sticks out a bit which meant that I had to mount the inner cover ring "inside out". Not a big deal, it's just a less snug fit against the face of the meter. After a couple of quick layers of paint I then secured the ring to the outer cover with some glue.

Here's the unit without the plastic cover. Speaking of which, the plastic cover was the next thing on the list.

I traced the outline from the old cover (which I couldn't use for two reasons; it was concave, touching the needle, and it had a hole for the clock setting knob). It turned out that the plastic I had bought cracked far too easy and I had to scrap my first attempt.

I traced the outline from the old cover (which I couldn't use for two reasons; it was concave, touching the needle, and it had a hole for the clock setting knob). It turned out that the plastic I had bought cracked far too easy and I had to scrap my first attempt.Despite doing my best not to scratch or crack the second cover it still cracked almost everywhere. At least I avoided the scratches and it turns out that when the unit is mounted in the instrument cluster the cracks aren't visible. If I had more time I'd redo it until it's perfect but I have to settle with this as I do not have more time.

Still, not to bad for a days work if you ask me.

Tuesday, February 6, 2007

Vacuum, interior and clock/tachometer swap

Unfortunately I didn't bring the camera with me this past Saturday as my brother needed it. Unfortunately because I actually made some progress as far as getting things back together in working condition instead of just taking things apart.

The first thing I got up and running was the vacuum for the heater system. I didn't test all vacuum diaphragms but those I did test worked so I'm cautiously optimistic as for the state of the others.

I also got the clock out of it's housing although I had to resort to violence as one pin broke loose, preventing me from removing the nut from it. I've been told that there's plenty of clocks to go around though so it wasn't too bothersome putting the hacksaw to it.

The next thing was to take apart my external Autometer tachometer which didn't prove to be all that taxing. After disassembling it I did a quick test fit in the old clock housing and I'll need to do quite a bit of fabrication in order to marry the two but it should be quite doable.

That's how far I got with the clock/tachometer project as I also started to straighten out and re-fasten a trimming that has come off from the roof on the drivers side (this is the best "before" picture I have of it).

This proved to be harder than I thought as I'm most likely missing some sort of clips or similar to fasten it with as no matter how I re-shaped it, it wouldn't stick to the ceiling properly.

I got a proper price estimate for a couple of parts ($50 for the wiper motor was some sort of delirious dream); the wiper motor is $165 and the high-speed fan motor relay is $19. Considering that I'd need to pay VAT, shipping and customs on these parts if I brought them in on my own from the states it's a very decent price.

Next up is to ask for a price quote on a couple of oil system mods from TA Performance that might be what I need (I had some concerns about the oil pressure of the engine when I got the car).

Oh, and I need to talk to the bank about a loan as well.

The first thing I got up and running was the vacuum for the heater system. I didn't test all vacuum diaphragms but those I did test worked so I'm cautiously optimistic as for the state of the others.

I also got the clock out of it's housing although I had to resort to violence as one pin broke loose, preventing me from removing the nut from it. I've been told that there's plenty of clocks to go around though so it wasn't too bothersome putting the hacksaw to it.

The next thing was to take apart my external Autometer tachometer which didn't prove to be all that taxing. After disassembling it I did a quick test fit in the old clock housing and I'll need to do quite a bit of fabrication in order to marry the two but it should be quite doable.

That's how far I got with the clock/tachometer project as I also started to straighten out and re-fasten a trimming that has come off from the roof on the drivers side (this is the best "before" picture I have of it).

This proved to be harder than I thought as I'm most likely missing some sort of clips or similar to fasten it with as no matter how I re-shaped it, it wouldn't stick to the ceiling properly.

I got a proper price estimate for a couple of parts ($50 for the wiper motor was some sort of delirious dream); the wiper motor is $165 and the high-speed fan motor relay is $19. Considering that I'd need to pay VAT, shipping and customs on these parts if I brought them in on my own from the states it's a very decent price.

Next up is to ask for a price quote on a couple of oil system mods from TA Performance that might be what I need (I had some concerns about the oil pressure of the engine when I got the car).

Oh, and I need to talk to the bank about a loan as well.

Tuesday, January 30, 2007

Vacuum, fan blower motor, wiper motor and surprises

This past weekend I got quite a bit done so let me break it down a bit.

This past weekend I got quite a bit done so let me break it down a bit.The vacuum

I decided to take a look at the lack of vacuum from point a to b and started in the engine bay. I quickly located the vacuum tank and in the process the reason for the absent vacuum; there's no hose connected from the engine to the vacuum tank.

Unfortunately I have no hose available but I'll buy me some at the local parts dealer and test this out this next Saturday. I'm not quite sure why the vacuum was disconnected but I'm hoping that it's not because it's busted.

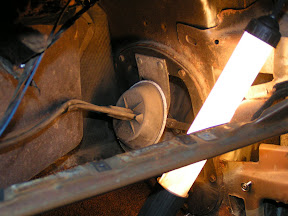

I was told that the nipple in this picture is the place to get the vacuum from. The nipple seems a bit bigger than the connection at the vacuum tank but I should be able to work that out.

The fan motor

I've been working on the car with the battery disconnected for various reasons and after figuring out how to troubleshoot the electric part of the heater control I hooked the battery back up. Imagine my suprise and joy when the fan control worked!

My only explanation is that there must have been a lot of corrosion on the connectors of the control and that me taking things apart removed the corrosion. The fan won't operate at the max speed but I was told that this is due to a faulty high speed relay. These can still be bought as a new spare which is what I'll do.

The wiper motor

The wiper motorI decided to take the wiper motor out as well while I was at it. This is most likely the cause for the non-operational washers as there's voltage all the way to the connectors at the motor.

These' aren't immensly expensive - around $50 if I recall correctly (I can't find the source right now though) so I'll buy one of these as well.

The bearings

I got hold of a company that can help me grind down the cam axle to correct tolerances and asked for a rough price estimate. The guy I talked to said that it could cost anything between $300 - $600 depending on the amount of work needed. Well, it's better than nothing and not too far from what I expected.

The surprises

While mucking about at the carburator in order to locate a good place to get the vacuum from I noticed something odd. The previous owner has jammed the choke valve wide open for some reason.

I've always felt like the car didn't perform as it should and used up a lot of gas - this might be why. I got a cable for this from Reijo though and after the engine is back in I'll try and fab a plate for hooking the knob up to the dash.

Rummagin about in the engine bay I also noticed that the generator and the AC compressor are misaligned. Talking to the guys over at V8Buick I learned that my generator is missing a bracket which might be the cause of the misalignment.

On top of this I discovered rust where I do not want it; right below the front windshield.

The fun never ends.

Sunday, January 21, 2007

The vacuum/heater control system

I've been going through the Buick factory manual I ordered from Detroit Iron Information Systems, reading up on the controls for the heater and A/C unit. Slowly I begin to understand just how the entire thing works (or should work at least).

Now, I won't be giving away the entire manual here, just a page or two in order to illustrate how it all works. If you need the manual - buy it. It really is worth the money, even though it can seem expensive.

The controls in the dash control both vacuum as well as electronics; the vacuum controls all the various doors in the system (there are 5 doors all in all; the defroster door, the mode door, the deflector door, the temperature door and the outside-recirculated air door).

The controls in the dash control both vacuum as well as electronics; the vacuum controls all the various doors in the system (there are 5 doors all in all; the defroster door, the mode door, the deflector door, the temperature door and the outside-recirculated air door).

The Fan switch controls the speed of the fan motor electronically as well as being the master vacuum switch. When you move the Fan switch to any position besides the "Off" position the outside-recirculated door is partially opened via a vacuum diaphragm.

The Temperature lever controls vacuum flow to the water valve; at the leftmost position no water from the radiator flows to the heater core and at the rightmost position the valve is fully opened.

Finally, the Selector switch controls the following doors via vacuum; the defroster door, the heater-air conditioner mode door and the outside-recirculated door. It is also mechanically linked to the A/C compressor clutch switch.

Vacuum is provided from a vacuum in the engine and goes through a vacuum tank to the master vacuum switch (the Fan switch, remember). The Temperature lever also receives vacuum directly from the tank so that the temperature of the air can be controlled without running the fan.

Vacuum is provided from a vacuum in the engine and goes through a vacuum tank to the master vacuum switch (the Fan switch, remember). The Temperature lever also receives vacuum directly from the tank so that the temperature of the air can be controlled without running the fan.

This means that if the master switch doesn't work, there'll be no vacuum to the Selector switch. It also means that you should be able to get warm air to flow through the system if you move the Temperature lever all the way to the right as this works without the master switch.

My guess is that if you don't get warm air through the system when driving your car with the Temperature lever all the way to the right with the Fan switch in the "Off" position you might have a vacuum problem. I can't say for sure though as I haven't checked on my own car yet.

You should also be able to measure voltage at the Fan switch in order to see if you have 12 volts at the 'F' pin (Brown wire). Following the wire diagram you should have 12 V out on all the other pins as well depending on what position the switch is in. These lead to various points in the fan blower resistor and from there on to the actual motor.

As for testing the vacuum, the easiest thing would probably be to run the engine on idle and then disconnecting the hose going to the vacuum tank in the engine bay (the 'in' connection on the tank) and feel if you have a vacuum there. If not, I'd guess your vacuum pump is busted.

If you do have vacuum you just connect the hose again and keep disconnecting hoses further down the chain until you find the leak. If there's vacuum all the way to a door diaphragm and the door still isn't moving then there's not much else to do than replace the diaphragm if you ask me.

As for the fan blower motor you should try and measure the resistor before you take apart half the car in order to get to the motor (it sits below the outer fender on the passenger side). There should be a wire running from the A/C box in under the fender from the engine bay. I can't tell you more as I have yet to do this but this is one advice I've been given.

There's a lot more to write on this subject but since I'm very much a beginner when it comes to troubleshooting this and keep guessing for most of the time I'll leave it be for the moment. Hopefully someone is helped by this information.

Feel free to post corrections, suggestions and ideas in the comments.

Now, I won't be giving away the entire manual here, just a page or two in order to illustrate how it all works. If you need the manual - buy it. It really is worth the money, even though it can seem expensive.

The controls in the dash control both vacuum as well as electronics; the vacuum controls all the various doors in the system (there are 5 doors all in all; the defroster door, the mode door, the deflector door, the temperature door and the outside-recirculated air door).

The controls in the dash control both vacuum as well as electronics; the vacuum controls all the various doors in the system (there are 5 doors all in all; the defroster door, the mode door, the deflector door, the temperature door and the outside-recirculated air door).The Fan switch controls the speed of the fan motor electronically as well as being the master vacuum switch. When you move the Fan switch to any position besides the "Off" position the outside-recirculated door is partially opened via a vacuum diaphragm.

The Temperature lever controls vacuum flow to the water valve; at the leftmost position no water from the radiator flows to the heater core and at the rightmost position the valve is fully opened.

Finally, the Selector switch controls the following doors via vacuum; the defroster door, the heater-air conditioner mode door and the outside-recirculated door. It is also mechanically linked to the A/C compressor clutch switch.

Vacuum is provided from a vacuum in the engine and goes through a vacuum tank to the master vacuum switch (the Fan switch, remember). The Temperature lever also receives vacuum directly from the tank so that the temperature of the air can be controlled without running the fan.

Vacuum is provided from a vacuum in the engine and goes through a vacuum tank to the master vacuum switch (the Fan switch, remember). The Temperature lever also receives vacuum directly from the tank so that the temperature of the air can be controlled without running the fan.This means that if the master switch doesn't work, there'll be no vacuum to the Selector switch. It also means that you should be able to get warm air to flow through the system if you move the Temperature lever all the way to the right as this works without the master switch.

My guess is that if you don't get warm air through the system when driving your car with the Temperature lever all the way to the right with the Fan switch in the "Off" position you might have a vacuum problem. I can't say for sure though as I haven't checked on my own car yet.

You should also be able to measure voltage at the Fan switch in order to see if you have 12 volts at the 'F' pin (Brown wire). Following the wire diagram you should have 12 V out on all the other pins as well depending on what position the switch is in. These lead to various points in the fan blower resistor and from there on to the actual motor.

As for testing the vacuum, the easiest thing would probably be to run the engine on idle and then disconnecting the hose going to the vacuum tank in the engine bay (the 'in' connection on the tank) and feel if you have a vacuum there. If not, I'd guess your vacuum pump is busted.

If you do have vacuum you just connect the hose again and keep disconnecting hoses further down the chain until you find the leak. If there's vacuum all the way to a door diaphragm and the door still isn't moving then there's not much else to do than replace the diaphragm if you ask me.

As for the fan blower motor you should try and measure the resistor before you take apart half the car in order to get to the motor (it sits below the outer fender on the passenger side). There should be a wire running from the A/C box in under the fender from the engine bay. I can't tell you more as I have yet to do this but this is one advice I've been given.

There's a lot more to write on this subject but since I'm very much a beginner when it comes to troubleshooting this and keep guessing for most of the time I'll leave it be for the moment. Hopefully someone is helped by this information.

Feel free to post corrections, suggestions and ideas in the comments.

Saturday, January 20, 2007

The cost of a hobby

Due to the horrible weather that greated me when I woke up this morning (I'd show you but Blogger is broken) I never went to the garage. There's not a lot I can do there either though due to the fact that my car's still sandwiched in between Anders an Reijo's cars. Another reason is a lack of funding.

I never expected working with a 35 year old car would be cheap or even economical but it's not until now I really realized how much this will cost me.

Replacing the front windshield will cost me approximately $110 (800 Skr). I need a new motor for the wiper washers which will set me back around $150-160 (1100-1200 Skr) if I recall correctly (can't find the link for it now).

I'm going to need to replace all the rod and crankshaft bearings in the engine and I have no idea how much this will cost me but I'm guessing at least $420 (3000 skr), probably more. On top of this I also have to replace the headers as they're broken. These cost $280 (2000 Skr).

This is just what I have to replace and we're already talking almost a thousand bucks. Besides this I would really like to get the heater working and although these components are rather cheap ($30 for a fan motor and about the same for the heater core) it all adds up.

If I decide to replace my 3.73 rear axle gears with new 3.08 gears the gears alone cost $170 (1200 Skr). I'll have to have someone to do it for me as well wich most likely will cost me another $210 (1500 Skr) if not more.

I really need to find a job that pays more.

I never expected working with a 35 year old car would be cheap or even economical but it's not until now I really realized how much this will cost me.

Replacing the front windshield will cost me approximately $110 (800 Skr). I need a new motor for the wiper washers which will set me back around $150-160 (1100-1200 Skr) if I recall correctly (can't find the link for it now).

I'm going to need to replace all the rod and crankshaft bearings in the engine and I have no idea how much this will cost me but I'm guessing at least $420 (3000 skr), probably more. On top of this I also have to replace the headers as they're broken. These cost $280 (2000 Skr).

This is just what I have to replace and we're already talking almost a thousand bucks. Besides this I would really like to get the heater working and although these components are rather cheap ($30 for a fan motor and about the same for the heater core) it all adds up.

If I decide to replace my 3.73 rear axle gears with new 3.08 gears the gears alone cost $170 (1200 Skr). I'll have to have someone to do it for me as well wich most likely will cost me another $210 (1500 Skr) if not more.

I really need to find a job that pays more.

Sunday, January 14, 2007

Getting the cluster out

Yesterday I finally got my instrument cluster out of the car, unfortunately it didn't do me a lot of good as far as the ventilation goes.

Yesterday I finally got my instrument cluster out of the car, unfortunately it didn't do me a lot of good as far as the ventilation goes.The climate control... eh, controls uses a combination of vacuum and electrics in order to control where and how the air goes. The switches that are up at the dashboard connects via vacuum lines to various vacuum controlled gates that in turn let hot or cold air into the system.

Vacuum lines are also used to control the speed of the fan. How this works I can't tell you because I don't know. And I don't know why this design was even used to begin with where electric switches and wires should be enough.

Anyhow, I can't just measure voltage at the switches because there are none to be measured as far as I can tell. The problem could be with the actual fan motor but as I have to remove the front passenger fender (and in the process the front bumper) in order to get to it (no kidding) I won't go there unless I really have to. Thus I've, once again, turned to the V8 Buick forum for advice.

Now that I have the cluster out I'm going to do two things; adjust the fuel meter as it shows 1/3 empty when the tank actually is empty and replace the clock with a tachometer. I have the one lying around that came with the car, bolted to the dash (looked ugly like hell). With a bit of luck I can fit it in the old clock housing.

Not a lot of work done but I kind of ran into a wall with all the disassembly overhead needed to get to the fan motor.

Saturday, January 6, 2007

Tackling the dashboard electronics

Today was the first day of real work on the car after I put it in a garage. I couldn't do very much as it's still sandwiched between Anders' and Reijo's cars so I decided to go ahead with the dashboard electronics.

Today was the first day of real work on the car after I put it in a garage. I couldn't do very much as it's still sandwiched between Anders' and Reijo's cars so I decided to go ahead with the dashboard electronics.I've tried to take the dash apart before with no luck but this time I had repair manual printouts by my side, something that improved the odds a lot. I still took my time doing things though, this being the first time I disassemble a 35 year old car.

Doing it "by the book" it took me about 3 hours getting the dash and the instrument cluster loose. I ran into problems getting the instrument cluster all the way out though - I'm guessing I need to unhook some tubes that the manual doesn't mention.

Soon after posting this I realised I've read somewhere on the Internet about how to remove the instrument cluster. After a minute's worth of brainstorming I recalled George Nenadovich most excellent instructions on how to do this. George's site is a great resource for Buick newbies like me - he has tons of great info.

Another thing I decided to take care of was the head light switch. The "bolt" that held it to the dash was broken off when I got the car. A member of the V8 Buick forum hooked me up with one free of charge (Hi Steve!) but I haven't had a chance to replace it yet.

Looking at the switch you could tell that it had taken damage from the water that has gotten into the car the past months. So I took it apart and cleaned it up. It turns out that it's a lot easier to keep the switch out of the cluster in order to get the cluster back into the dash so I never did mount it. It should work better now though.

I also took a quick look at the front windshield. Reijo knows a guy who can replace it for me for about $115 (800 Skr) so that's what I'll do - it's a lot better option than having me replacing it, probably making it worse in the process.

Subscribe to:

Posts (Atom)